Processing and Properties of Plastic Lumber

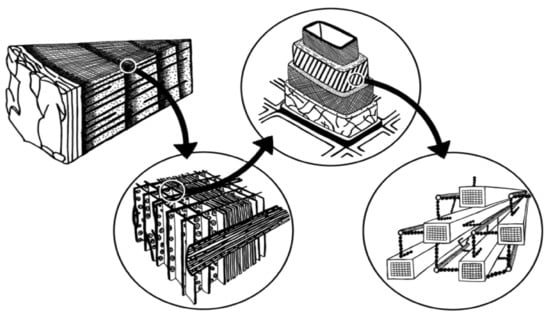

Plastic residue can be processed into composites using wood flour, mineral fillers, plant or synthetic fibers to obtain plastic lumber, a substitute material for natural wood. The composition and processing conditions are largely responsible for the final characteristics of the plastic lumber. Factors such as density, particle size and moisture content in the material to be processed require extruders with specific technical characteristics, in order to reduce the residence time of the plastic inside the equipment, maintain a constant feed rate and ensure good degassing and homogenization of the components. The composites can be manufactured using single-screw, co- or counter-rotating conical or parallel twin-screw extruders. Plastic lumber exhibits different physical and mechanical properties from natural wood, including lower stiffness (elastic modulus) and superior weathering resistance.

Polymers, Free Full-Text

What is Wood Plastic Composite?

Wood–Plastic Composite Technology

Visual comparison of surface finish (16.5x14 cm2) of sample without (a)

Thermal and flammability properties of polyethylene composites with fibers to replace natural wood - Jairo da Silva Rocha, Viviane A Escócio, Leila LY Visconte, Élen BAV Pacheco, 2021

Prospective evaluation of circular economy practices within plastic packaging value chain through optimization of life cycle impacts and circularity - ScienceDirect

PDF) Processing and Properties of Plastic Lumber

Recycled carpet-reinforced composites from post-consumer polypropylene carpet and recycled HDPE resin - ScienceDirect

Nebraska MRF adds plastic-lumber manufacturing line

Performance Analysis of CFS Encased Recycled Plastic Laminate Beam