Metallurgy - Casting, Alloying, Refining

Metallurgy - Casting, Alloying, Refining: Casting consists of pouring molten metal into a mold, where it solidifies into the shape of the mold. The process was well established in the Bronze Age (beginning c. 3000 bc), when it was used to form most of the bronze pieces now found in museums. It is particularly valuable for the economical production of complex shapes, ranging from mass-produced parts for automobiles to one-of-a-kind production of statues, jewelry, or massive machinery. Casting processes differ in how the mold is made and in how the metal is forced into the mold. For metals with a high melting temperature, stable refractory

Metallurgy, art and science of extracting metals from their ores and modifying the metals for use.

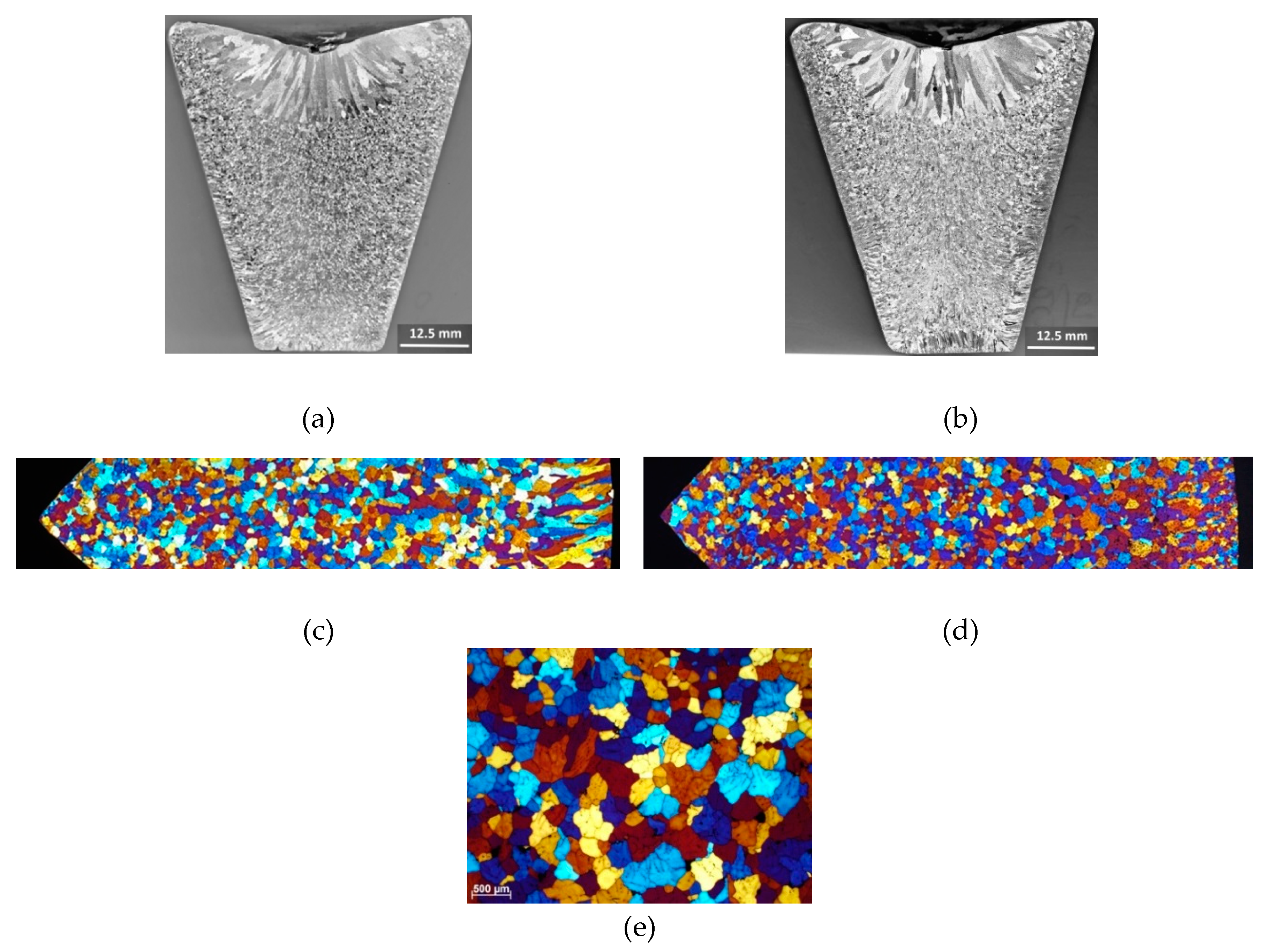

Grain refinement mechanism and its effect on mechanical properties and biodegradation behaviors of Zn alloys – A review - ScienceDirect

Metals, Free Full-Text

Foundry and Casting Metallurgy for Dummies

Metallurgy - Refining, Alloying, Smelting

PDF) A R C H I V E S Influence of refining process on the porosity of high pressure die casting alloy Al-Si

New Insights into Silicon Purification by Alloying–Leaching Refining: A Comparative Study of Mg–Si, Ca–Si, and Ca–Mg–Si Systems

Flux refining process 5 . Download Scientific Diagram

Specialist Melting - Materials Processing Institute

Metals, Free Full-Text

Metallurgy - Casting, Alloying, Refining