GRAPHITE MOLD CASTING AND ITS ADVANTAGES – Graphiteprocessing

Modern methods of manufacturing high resistance cast parts can involve complicated processes or expensive machinery and supplies. Several graphite mold suppliers have the in-house capability to manufacture excellent standard and accurate graphite permanent molding tooling while saving up to 75 percent on tooling costs. A single mold will produce up to 25,000 castings. BENEFITS OF…

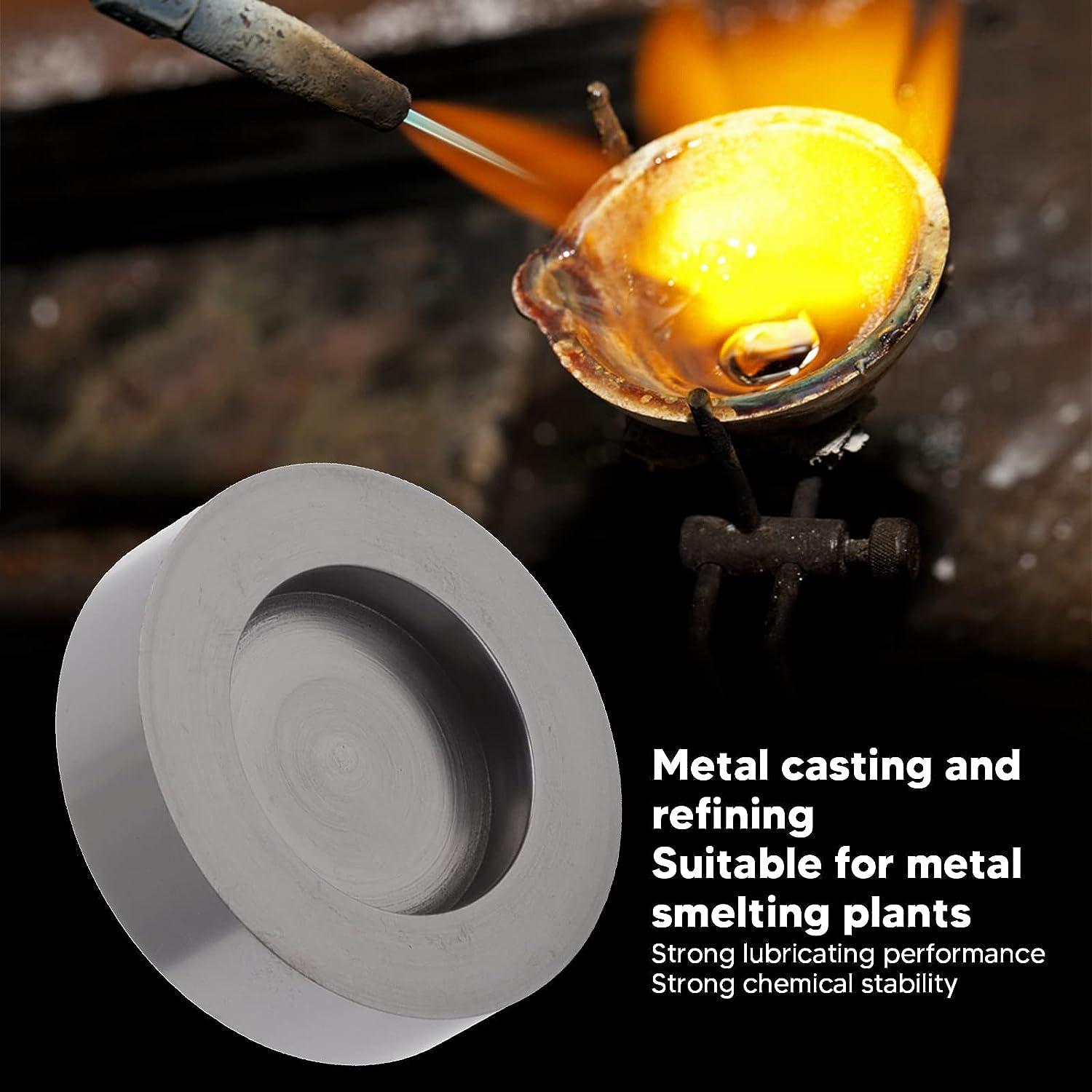

Factory Sells High Quality Graphite Mold Casting Graphite Mould Casting

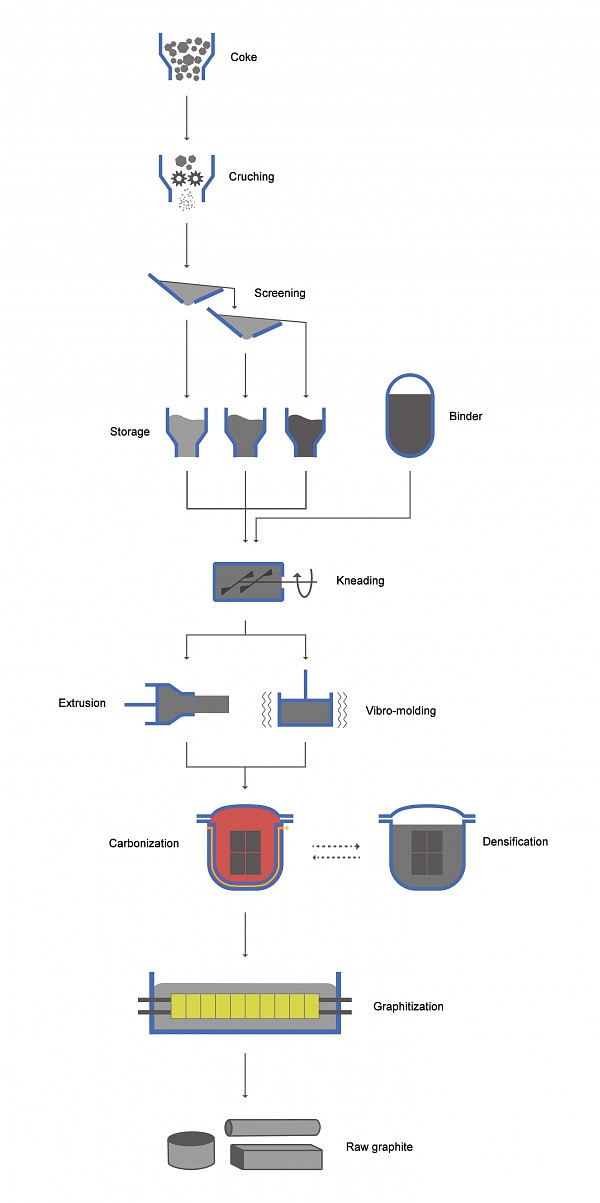

Graphite manufacturing process - GAB Neumann

Custom design graphite mold

Advantages of Using Graphite Molds, by Nancy Nie

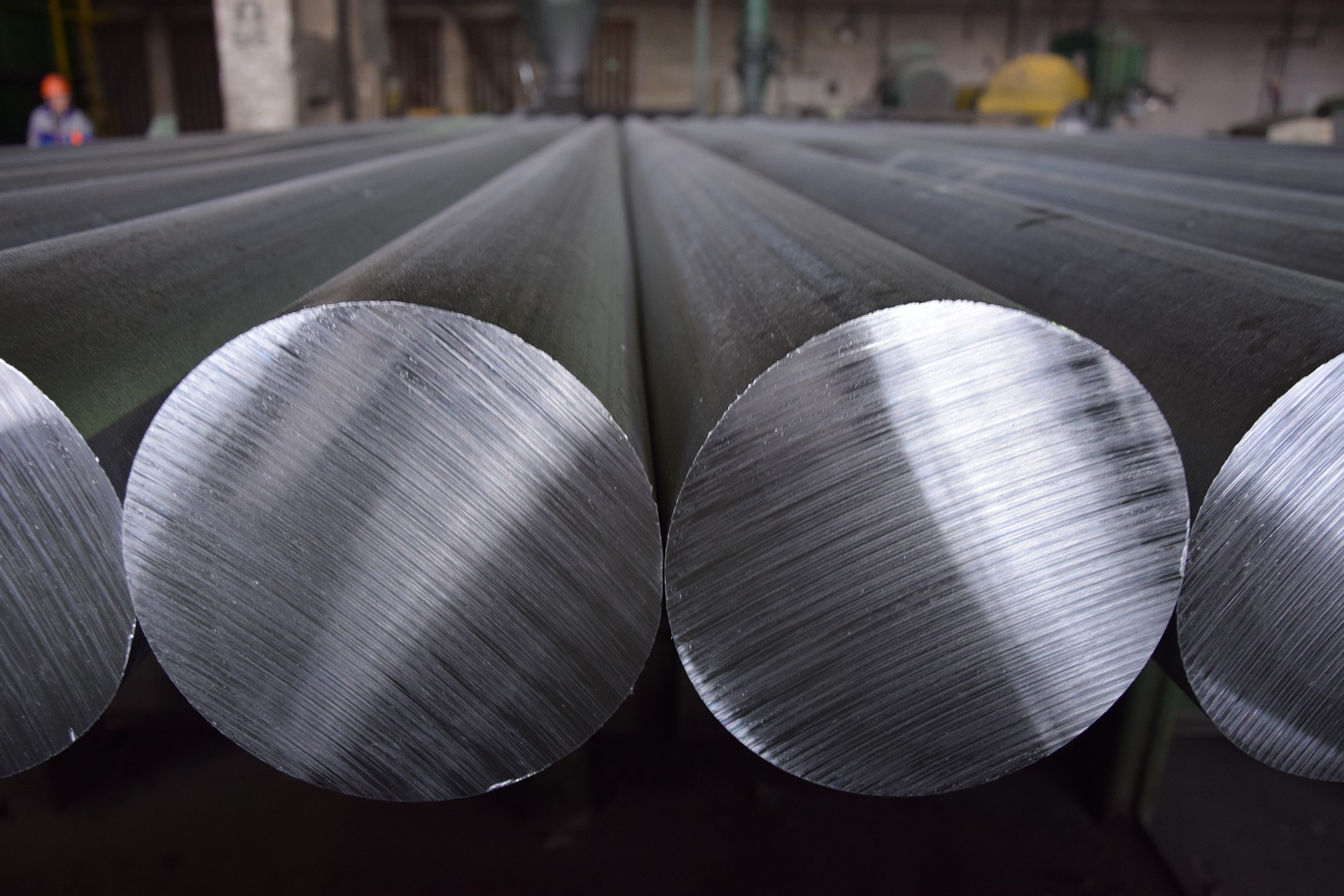

Durable Graphite Mold Ulized for Non - Ferrous Metal Continuous Casting - China Diamond Tools Applications Molds, Carbon Graphite Mold

Graphite Mold Casting is a Better Solution All Around

Advantages of using graphite molds in the copper alloy casting process

Quality Graphite Material: made of quality graphite material, the ingot molds won't affect the metal purity during the metal refining process; Fast

3 Pieces Heart Star Cross Graphite Casting Ingot Mold Metal Refining Scrap Melting Casting Mould for Smelting Gold Silver Metal Aluminum Copper Brass

Factory Sells High Quality Graphite Mold Casting Graphite Mould Casting

Graphite Casting Mold for Titanium Pump Valve Body

Graphite manufacturing process - GAB Neumann

Graphite Dies & Molds Help Industrial Production More Efficient

copper electrode graphite electrode machining for EDM

4 Key Advantages to Using a Graphite Mold Casting Service - Graphicast

Graphite casting die for tube continuous casting of non ferrous metals Supplier